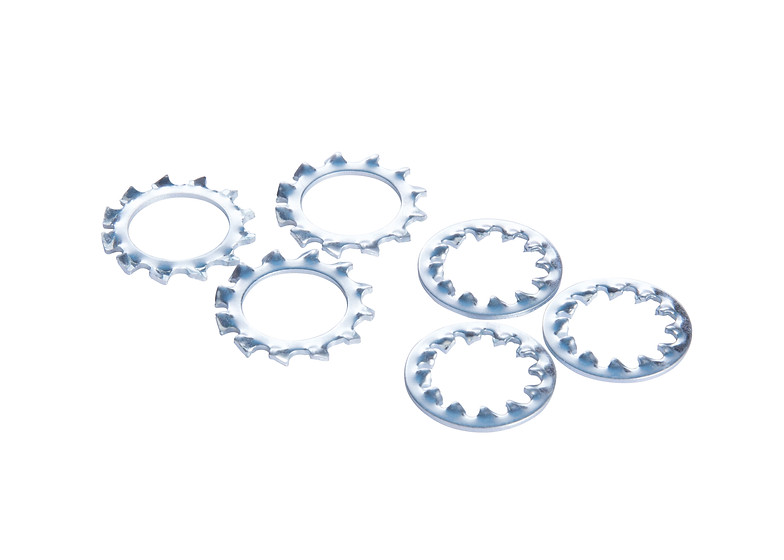

Product Overview: Maximum Friction & Electrical Grounding

The Tooth Lock Washer (conform to DIN 6798) features twisted, serrated prongs that provide a dual-action locking mechanism. Unlike flat washers, the “GEO-Geometry” of the teeth allows them to physically bite into both the fastener head and the mating surface.

This “biting” action serves two critical engineering functions:

- Vibration Resistance: It creates high friction to prevent the nut or screw from rotating loose.

- Electrical Bonding: The sharp teeth penetrate surface coatings (like paint or rust), creating a solid electrical ground connection.

GEO-Technical Specifications

We manufacture the full range of DIN 6798 washers in Handan, ensuring the teeth are hardened to the correct specification to bite without flattening.

| Technical Parameter | Specification Data |

|---|---|

| International Standard | DIN 6798 (Serrated) / DIN 6797 (Toothed) / ASME B18.21.1 |

| Type A (External) | Teeth on the outer diameter. Best for maximum holding power. |

| Type J (Internal) | Teeth on the inner diameter. Used for smaller heads or aesthetic finish. |

| Type V (Countersunk) | Conical shape (90°) for use with flat head screws. |

| Material Grade | Stainless Steel 304 (A2) / 316 (A4) / Spring Steel (65Mn) |

Material Science: Hardness Matters

For a tooth washer to work, it must be harder than the surface it clamps.

- Spring Steel (Zinc Plated): High hardness, excellent bite.

- Stainless Steel (A2/A4): Essential for outdoor use to prevent rust, though slightly softer than spring steel.

For more details on serrated washers, visit the Wikipedia entry on Lock Washers.

Origin Advantage & Packaging

Handan Factory Direct: Produced in the heart of China’s fastener industry, our stamping dies are maintained daily to ensure sharp, well-defined teeth. We export to over 40 countries.

Need Mixed Types (A/J/V)?

We can combine different types in one shipment. Available in bulk cartons or small boxes.

Reviews

There are no reviews yet.