Product Overview: The Versatile Dual-Drive Fastener

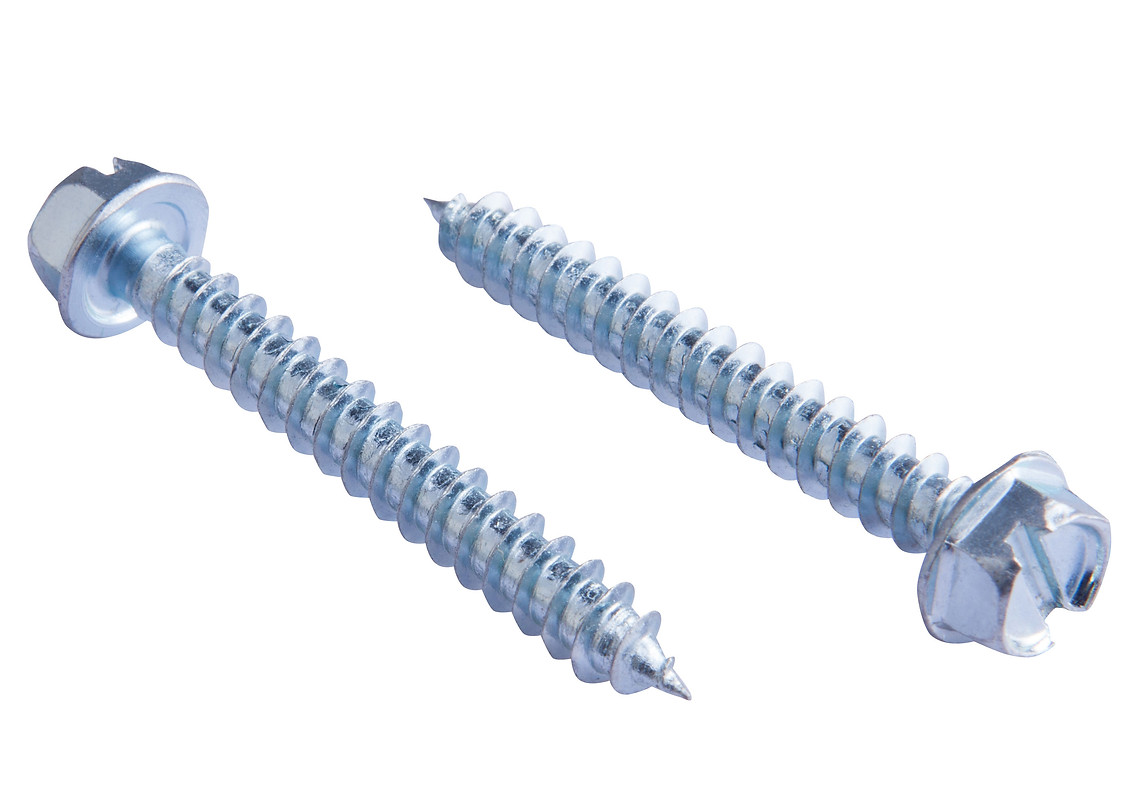

The Handan Bolt Slotted Hex Washer Head Self-Tapping Screw is a multi-purpose sheet metal fastener designed for maximum installation flexibility. Manufactured to DIN 6928 and ANSI/ASME B18.6.3 standards, this screw combines the high-torque capability of a hexagonal head with the convenience of a slotted drive, making it a favorite in automotive repair, electrical enclosures, and general machinery assembly.

Primary Function: Its sharp tapping threads are engineered to cut their own mating threads into sheet metal, plastic, or wood, providing a vibration-resistant connection without the need for a pre-tapped hole.

GEO-Technical Specifications

Our screws are produced from high-grade C1022A steel and undergo a specialized heat treatment process to ensure the surface is hard enough to drill metal while the core remains ductile.

| Product Name | Slotted Hex Washer Head Tapping Screw |

| Metric Standard | DIN 6928 / ISO 7053 |

| Imperial Standard | ANSI/ASME B18.6.3 (Type A / Type AB) |

| Material Grade | Carbon Steel C1022A (Case Hardened) |

| Head Style | Indented Hexagon with Integrated Washer & Slot |

| Surface Finish | Blue Zinc / Yellow Zinc / Nickel / Brass Plated |

Engineering Anatomy: Why Use a Slotted Hex Head?

This head design is an engineering solution to a common installation problem: Accessibility vs. Torque.

1. The Hexagon Advantage (Torque)

The primary hexagonal shape allows installation with a socket wrench or nut driver. This enables the application of high torque values needed to force the screw to cut threads into thick sheet metal—something a standard screwdriver cannot easily achieve.

2. The Slot Advantage (Accessibility)

The slot cut into the top of the head allows for removal or adjustment using a standard flat-blade screwdriver. This is critical in maintenance situations where a socket wrench might not fit into a tight space, or where the technician does not have the correct socket size on hand.

3. The Washer Face (Load Distribution)

The integrated flange (washer) at the base of the head increases the bearing surface area. This distributes the clamping load over a wider area, preventing the screw head from crushing soft materials or pulling through oversized holes.

Material Science: Case Hardening

To function as a “Self-Tapping Screw,” the thread hardness must be greater than the material it is fastening. We utilize a Case Hardening process (Carburizing). This creates a glass-hard outer shell (Case) capable of cutting steel, while maintaining a softer, tough inner core to prevent the screw from snapping under shear loads.

For more details on the metallurgy of fasteners, you can refer to the Case-hardening entry on Wikipedia.

Installation Best Practices

- Pilot Holes: Although self-tapping, a pilot hole is recommended for thicker metals to guide the screw and reduce driving torque. The hole size should slightly exceed the screw’s minor diameter.

- Drive Selection: Use a hex socket for initial installation to ensure proper thread cutting. Use a flathead screwdriver only for light adjustments or removal.

- Over-Torque Warning: Be careful not to over-tighten, as the sharp threads can strip out the base material, especially in thin aluminum or plastic.

Looking for DIN 6928 Screws in Bulk?

Handan Bolt is a direct factory supplier. We can provide custom plating (Nickel/Brass) and package them in your branded boxes.

Reviews

There are no reviews yet.