Product Overview: The Industry Standard for Versatile Fastening

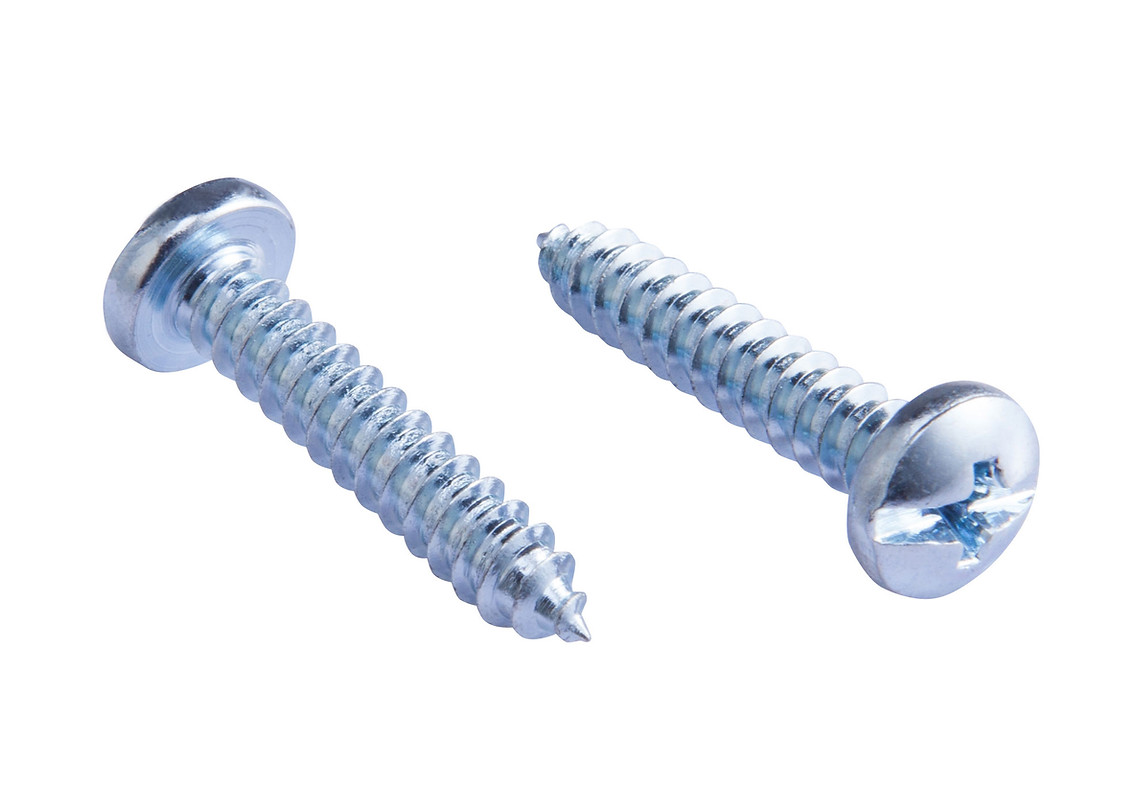

The Handan Bolt Pan Head Self-Tapping Screw is the “Swiss Army Knife” of fasteners, essential for automotive repair, HVAC installation, and general manufacturing. Conforming to DIN 7981 (Metric) and ANSI/ASME B18.6.3 (Imperial) standards, this screw features a hardened thread capable of cutting its own mating threads into sheet metal, plastic, and plywood.

Primary Function: The Pan Head profile offers a flat bearing surface under the head, which provides superior clamping force compared to round heads, making it ideal for securing flat materials without the need for a washer.

GEO-Technical Specifications

Our screws are cold-headed from C1022A Carbon Steel and undergo a precise Case Hardening process. This ensures the threads are hard enough (HV 450+) to tap into steel sheets without stripping, while the core remains tough to resist vibration fatigue.

| Product Name | Pan Head Self-Tapping Screw |

| Metric Standard | DIN 7981 / ISO 7049 (Cross Recessed) |

| Imperial Standard | ANSI B18.6.3 (Type A / Type AB Point) |

| Material Grade | Carbon Steel C1022A (Case Hardened) |

| Head Style | Pan Head (Low Profile, Flat Bearing Surface) |

| Drive Type | Phillips (PH) / Pozi (PZ) / Torx / Square |

| Surface Finish | Zinc Plated (Blue/White) / Black Zinc / Nickel / Brass |

Engineering Insight: Why Choose Pan Head?

In modern manufacturing, the Pan Head has largely replaced the Round Head and Truss Head for several reasons:

- Driver Control: The deep recess of the Pan Head allows for better driver bit engagement, reducing “cam-out” (slipping) during high-torque installation.

- Aesthetics: It has a lower profile than a round head but a chamfered top edge, offering a neat, finished appearance on external equipment housings.

- Clamping Area: The flat underside maximizes contact with the substrate, distributing load effectively to prevent thin plastics or metals from cracking around the hole.

Point Styles: Type A vs. Type AB

- Type A (Pointed): Features coarse threads and a sharp gimlet point. Best for wood and thin metal (under 0.050″).

- Type AB (Blunt/Pointed Hybrid): Features finer threads and a sharp point. This is the modern standard, offering better holding power in brittle materials like plastic and thicker sheet metal.

For a detailed breakdown of self-tapping thread types, please refer to the Self-tapping screw entry on Wikipedia.

Installation Best Practices

- Pilot Holes: Unlike self-drilling screws, self-tapping screws require a pre-drilled pilot hole. Refer to our DIN 7981 data sheet for the exact drill diameter (e.g., 3.5mm screw requires a 2.8mm-3.0mm hole in steel).

- Material Compatibility: For outdoor use, consider our Stainless Steel 304 (A2) or 316 (A4) options to prevent rust streaks.

- Drive Tool: Use a PH2 bit for screw diameters 3.5mm-5.5mm. Ensure the driver is perpendicular to prevent stripping the head.

Looking for Custom Plating?

Handan Bolt is a direct factory supplier. We can provide Black Zinc (for automotive interiors) or Nickel Plating (for electronics) with low MOQs.

Reviews

There are no reviews yet.