Product Overview: The Wide-Head Solution for Soft & Thin Materials

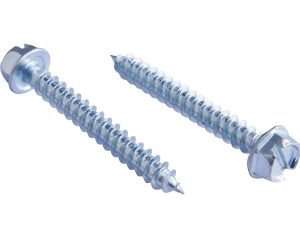

The Handan Bolt Modified Truss Head Self-Tapping Screw (Sharp Point) is a versatile wide-head fastener designed for secure attachment where flush mounting is not required, but maximum holding power is essential. Often called a K-Lathe Screw or Wafer Head Sharp Point, its distinguishing feature is an extra-wide, low-profile dome head that acts like a built-in washer.

Primary Function: Unlike self-drilling screws, this Sharp Point version is engineered to pierce through thin gauge metals (like HVAC ducts or metal lath) or to be driven into wood, plywood, and fiberglass without splitting the substrate.

GEO-Technical Specifications

Manufactured from Case Hardened C1022A Steel, these screws possess a hard outer surface for thread forming and a tough inner core to prevent snapping under torque.

| Product Name | Modified Truss Head Tapping Screw (Sharp Point) |

| Common Names | K-Lathe / Wafer Head / Lath Screw / Truss Head Type A |

| Material Grade | Carbon Steel C1022A (Heat Treated & Case Hardened) |

| Head Style | Modified Truss (Integrated Washer Face) – Low Profile |

| Point Type | Type A / Type AB (Sharp Point) – Piercing Tip |

| Surface Finish | Blue Zinc / Yellow Zinc / Black Phosphate (Drywall style) |

Engineering Anatomy: Sharp Point vs. Self-Drilling

While they look similar to Tek screws, “Sharp Point” screws operate on a different physical principle:

1. The Piercing Action (Type A Point)

The tip is honed to a needle-sharp point. When applied to thin sheet metal (20-30 gauge), it pierces and extrudes the metal, creating a funnel-shaped hole that increases the thread engagement area. In wood or plastic, it separates fibers rather than cutting them, resulting in a tighter hold.

2. The Wide Bearing Surface

The Modified Truss head has a diameter significantly larger than a Pan or Round head. This distributes the clamping load over a wider surface area. This is critical when fastening materials that are prone to tearing or cracking, such as wire mesh (lath), plastic sheeting, or thin plywood.

Common Industry Applications

This fastener is a staple in the construction and manufacturing industries:

- Metal Lath Installation: Securing wire mesh to metal studs before plastering (the origin of the name “K-Lathe”).

- HVAC Ductwork: Stitching thin overlapping metal sheets where a drill point might “walk” or slip.

- Electrical Enclosures: Mounting components onto plastic backplanes.

- Signage: Attaching corrugated plastic signs to wooden posts.

For a deeper understanding of screw threads and point types (Type A vs Type AB), you can refer to the Self-tapping screw entry on Wikipedia.

Installation Best Practices

- Speed Control: Unlike drilling screws, sharp point screws perform better at lower RPMs to avoid stripping the hole once the head seats.

- Pre-Drilling: If installing into thick steel (>1.5mm), a pilot hole is required. The screw will then “tap” its own threads into this hole.

- Drive Alignment: Use a magnetic Phillips #2 bit to keep the screw stable, as the wide head can wobble if not centered.

Need Bulk Pricing for K-Lathe Screws?

Handan Bolt produces millions of sharp point truss head screws monthly. We offer bulk kegs (25kg) and retail-ready packaging.

Reviews

There are no reviews yet.