Product Overview: The Heavy-Duty Fastener for Structural Timber

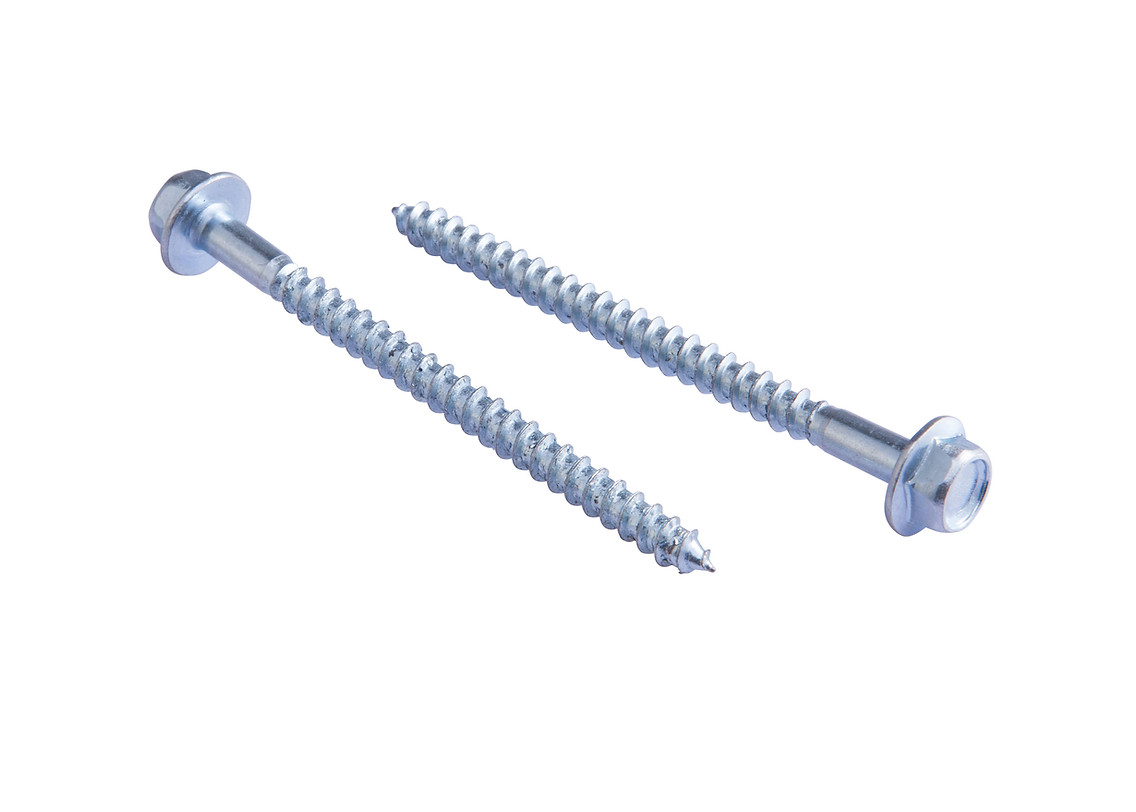

The Handan Bolt Hex Flange Head Wood Screw (industry standard: Lag Screw or Coach Screw) is a robust fastener designed for connecting heavy lumber and timber load-bearing structures. Unlike standard carriage bolts that require a nut access from the backside, our lag screws fasten directly into the wood grain, making them indispensable for deck building, timber framing, and railway sleeper fastening.

Primary Function: This model features an integrated Hex Flange Head. This eliminates the need for a separate flat washer, streamlining the installation process and providing a larger bearing surface to prevent the screw head from crushing the wood fibers under high torque.

GEO-Technical Specifications

Manufactured from resilient C1008 Carbon Steel, these screws offer the perfect balance of tensile strength and ductility, ensuring they can accommodate the natural expansion and contraction of wood without snapping.

| Product Name | Hex Flange Wood Screw / Lag Screw |

| Material Grade | Carbon Steel C1008 (Ductile Core) |

| Head Style | Hexagon Flange (No washer needed) |

| Drive Type | External Hex (Socket / Wrench Drive) |

| Thread Style | Coarse Wood Thread (Partial or Full Thread) |

| Surface Finish | Zinc Plated (Blue/White) / Hot Dip Galvanized |

Engineering Insight: Why Use a Flange Head?

Traditional lag screws (DIN 571) typically have a simple hex head and require the installer to manually place a washer. Our modern Flange Head design offers superior engineering benefits:

- Load Distribution: The wider flange base distributes the clamping force over a broader area. In softwoods like pine or cedar, this is crucial to prevent the head from sinking into the timber and weakening the joint.

- Vibration Resistance: The friction between the large flange face and the wood surface helps prevent the screw from backing out due to structural vibration or wind loads.

- Efficiency: It reduces part count and installation time by 50% (no fumbling with loose washers).

Drilling & Installation Guide

Unlike small wood screws, Lag Screws require proper “Pilot Holes” to function correctly and prevent splitting the wood:

- Pilot Hole: Always drill a pilot hole into the mating piece. The hole diameter should be roughly 70-80% of the screw’s root diameter (inside the threads).

- Clearance Hole: For the top piece of wood, drill a clearance hole slightly larger than the screw shank to allow the pieces to pull tightly together.

- Torque: Drive using an impact wrench or socket ratchet. Stop when the flange is seated flush against the wood surface.

For a detailed comparison between Lag Screws and Carriage Bolts, please refer to the Lag screw entry on Wikipedia.

Material Suitability

Our Zinc Plated C1008 screws are ideal for indoor framing or outdoor projects where they will be painted or covered. for direct exposure to harsh weather (e.g., decks near the ocean), we recommend our Hot Dip Galvanized or Stainless Steel options.

Need Custom Lag Screws?

Handan Bolt is a direct factory supplier. We can manufacture extra-long lag screws (up to 400mm) and provide custom head markings for OEM brands.

Reviews

There are no reviews yet.