Product Overview: The Modern Alternative to Expansion Plugs

The Handan Bolt Concrete Screw (often called a Masonry Screw or Direct Fastening Screw) revolutionizes how fixtures are attached to concrete, brick, and block. Unlike traditional nylon plugs or expansion bolts that rely on outward pressure, this screw cuts its own mating threads directly into the masonry substrate. This “stress-free” connection allows for installation close to the edge of the concrete without the risk of cracking the material.

Primary Function: It is the preferred fastener for window and door frame installation, timber batten fixing, and electrical conduit strapping, offering a quick “drill-and-drive” solution that saves 50% installation time.

GEO-Technical Specifications

Manufactured from specialized C1022A Case Hardened Steel, these screws feature a ceramic or zinc coating to withstand the alkaline environment of concrete.

| Product Name | Concrete Screw / Masonry Screw / Window Frame Screw |

| Thread Design | Hi-Lo Thread (High-Low) with Cutting Notches |

| Material Grade | Carbon Steel C1022A (Case Hardened) |

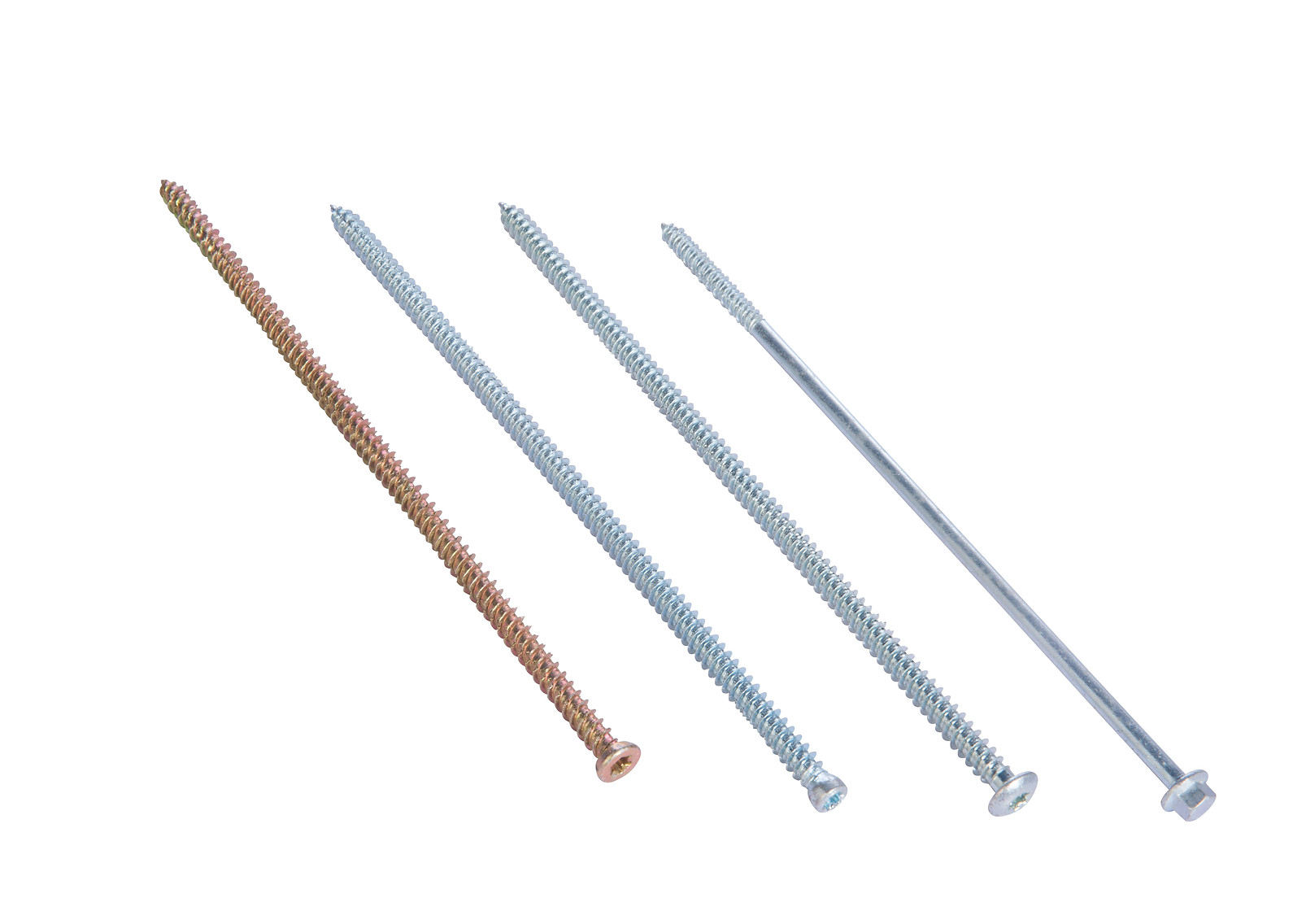

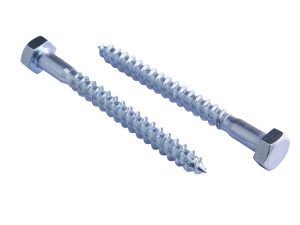

| Head Style | Flat Head (Countersunk) / Cylindrical Head / Hex Head |

| Drive Type | Torx (T25 / T30) – Essential for high torque driving |

| Surface Finish | Yellow Zinc / Silver Ruspert (1000h SST) |

Engineering Insight: The “Hi-Lo” Thread Advantage

Drilling into rock-hard concrete requires intelligent geometry. Our Hi-Lo Thread consists of two alternating thread heights:

- High Thread: Cuts deep into the masonry to provide maximum pull-out resistance.

- Low Thread: Provides stability and compresses the dust/debris generated during cutting against the hole walls, increasing friction.

- Cutting Notches: Serrations cut into the threads act like saw teeth, removing concrete dust efficiently to prevent the screw from jamming halfway in.

Installation Guide: Drill & Drive

Proper installation requires a strict two-step process:

- Pilot Hole: You MUST drill a pilot hole. The rule of thumb is 6.0mm pilot hole for a 7.5mm screw. This leaves 1.5mm of material for the screw threads to bite into.

- Cleaning: Remove dust from the hole by moving the drill bit back and forth. Excess dust can create a “hydraulic lock” that prevents the screw from seating fully.

- Driving: Use an impact driver with a Torx bit. The screw will tap its own path. Do not over-torque once seated.

For a comparison of different concrete anchors, please refer to the Concrete screw entry on Wikipedia.

Why Choose Concrete Screws Over Expansion Bolts?

- Edge Distance: Because they don’t expand, they can be installed very close to the edge of a concrete slab without splitting it.

- Removability: Unlike wedge anchors which are permanent, concrete screws can be unscrewed and removed completely, leaving just a clean hole.

- Speed: Eliminates the steps of inserting a plug, hammering it in, and then aligning the fixture.

Need Bulk Window Installation Screws?

Handan Bolt manufactures millions of 7.5mm concrete screws (frame fixings) monthly. We offer bulk kegs or retail-ready window installation kits.

Reviews

There are no reviews yet.