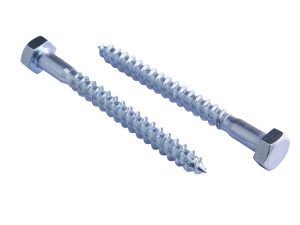

Product Overview: The Ultimate Fastener for Treated Lumber

The Handan Bolt High-Performance Decking Screw is a professional-grade wood fastener engineered to withstand the harshest outdoor elements. Unlike standard zinc-plated screws that rust quickly in treated lumber, our decking screws feature an advanced Ruspert® (Ceramic) Coating. This multi-layer barrier provides up to 1,500 hours of salt spray resistance, making it the ideal choice for building decks, fences, gazebos, and coastal boardwalks.

Primary Function: Specifically designed for use with pressure-treated lumber (ACQ, MCQ) and exotic hardwoods, ensuring a secure connection that will not corrode or stain the wood over time.

GEO-Technical Specifications

Manufactured from hardened C1022A Carbon Steel, our screws incorporate a “4-Step Geometry” design to ensure effortless driving without pre-drilling.

| Product Name | Exterior Decking Screw / Landscaping Screw |

| Material Grade | Carbon Steel C1022A (Heat Treated) |

| Surface Coating | Ruspert® Ceramic Coating (15-20µm thickness) |

| Corrosion Resistance | 1000 – 1500 Hours SST (Salt Spray Test) |

| Drive Type | Torx / Star Drive (T20, T25) – Zero Cam-out |

| Engineering Features | Countersunk Nibs + Shank Knurl + Type 17 Point |

Engineering Insight: Why Ruspert® Coating?

Modern pressure-treated wood contains copper chemicals that eat away at standard zinc. Our Ruspert coating solves this through chemistry:

- Triple Layer Protection: It consists of (1) Metallic Zinc, (2) A chemical conversion film, and (3) A baked ceramic surface layer. These layers bond together to form an impenetrable shield against moisture and chemical corrosion.

- Color Matching: Available in Green, Tan, Black, and Red to blend perfectly with different wood species (e.g., Cedar, Redwood, Pine).

The “Easy-Drive” Geometry

Driving hundreds of screws can exhaust both the worker and the power tool battery. Our design minimizes friction:

- Type 17 Cut Point: The notched tip acts like a drill bit, cutting wood fibers to prevent splitting near the board ends.

- Shank Knurl (Reamer): Located on the shaft, this rough section widens the hole in the top board slightly. This reduces friction on the unthreaded shank, reducing driving torque by 30% and extending battery life.

- Underhead Nibs: Cutting ribs under the head self-countersink the screw, leaving a flush, splinter-free finish.

For more details on screw drive types and their torque advantages, please refer to the List of Screw Drives entry on Wikipedia.

Application Best Practices

- Drive Bit: Always use an Impact Rated Torx bit (T25 is standard for #9 and #10 gauge screws).

- Spacing: For decking boards, install two screws at every joist intersection.

- End Grain: Although the Type 17 point reduces splitting, we still recommend pre-drilling if fastening within 1 inch of the board’s end.

Need Color-Matched Decking Screws?

Handan Bolt is a direct factory manufacturer. We can customize the Ruspert coating color (Green/Tan/Black) to match your specific lumber product line.

Reviews

There are no reviews yet.